Cutting boards are essential in every kitchen, playing a vital role in food preparation. Like any other kitchen tool, they require proper maintenance to ensure longevity and hygiene. One common method of preserving wood cutting boards is the application of mineral oil. This practice enhances the cutting board’s appearance and helps preserve the wood, making it more resilient to wear and tear. Using mineral oil for wood cutting boards has become popular among chefs and home cooks, as it offers an effective and safe way to maintain this essential kitchen tool.

Why Use Mineral Oil?

The Benefits of Mineral Oil

Mineral oil, especially when it’s food grade, has unique properties that make it an ideal choice for preserving wood cutting boards. Here’s why:

- Moisture Retention: Mineral oil helps retain moisture within the wood, preventing it from drying out and cracking. This ensures that the cutting board remains smooth and functional for longer.

- Food Safety: Unlike other oils, food-grade mineral oil doesn’t turn rancid. It’s odorless and tasteless, ensuring that it doesn’t affect the flavor of the food. This makes it a safe option on cutting boards where food is prepared.

- Enhanced Appearance: Regular application of mineral oil enhances the appearance of the wood, giving it a rich and glossy finish. It brings out the natural grain and color of the wood, adding to the aesthetic appeal of the cutting board.

- Easy to Apply: Mineral oil is readily available and easy to apply. A simple wipe-down with a cloth soaked in mineral oil can rejuvenate the appearance and functionality of a wood cutting board.

- Affordability: Mineral oil is relatively inexpensive compared to specialized wood care products. It offers an economical solution for maintaining cutting boards without compromising quality or safety.

Safety Considerations

When choosing mineral oil for your wood cutting board, it’s essential to select a product labeled as “food grade.” This ensures the oil meets specific safety standards suitable for contact with food. Non-food-grade mineral oils may contain unsafe substances, so always check the label before purchasing.

How to Apply Mineral Oil

Applying mineral oil to a wood cutting board is a straightforward process that anyone can do. Regular application helps maintain the cutting board’s appearance and functionality. Here’s a step-by-step guide on how to properly apply mineral oil to your cutting board:

Step 1: Clean the Cutting Board

Before applying mineral oil, ensure the cutting board is clean and dry. Wash it with mild soap and water, then dry it thoroughly with a clean towel. Allow it to air dry completely to ensure no moisture is trapped within the wood.

Step 2: Choose the Right Mineral Oil

Select a food-grade mineral oil that’s specifically designed for use on cutting boards. This ensures that the oil is safe for contact with food and won’t affect the taste or smell of your meals.

Step 3: Apply the Mineral Oil

Pour a small amount of mineral oil onto a clean, soft cloth or paper towel. Gently rub the oil into the wood, following the grain’s direction. Ensure that the entire surface of the cutting board is covered, including the sides and edges.

Step 4: Allow the Oil to Soak

Let the mineral oil soak into the wood for at least 20 minutes. This allows the oil to penetrate deeply into the wood fibers, providing maximum protection and moisture retention.

Step 5: Wipe Off Excess Oil

After allowing the oil to soak, wipe off any excess oil using a clean, dry cloth. This ensures that no oily residue left on the surface could transfer to food.

Step 6: Repeat if Necessary

You may need to repeat the process for cutting boards that are extremely dry or haven’t been oiled in a while. Following the same steps, apply a second coat of mineral oil to ensure complete coverage and protection.

Step 7: Regular Maintenance

Regularly applying mineral oil to your wood cutting board helps maintain its appearance and functionality. Depending on how often you use the cutting board, you may need to oil it monthly or even more frequently.

Alternatives to Mineral Oil

While mineral oil is a popular choice for maintaining wood cutting boards, several other oils can be used as alternatives. Each of these alternatives has its unique properties, benefits, and drawbacks. Here’s a closer look at some common alternatives to mineral oil for cutting boards:

1. Coconut Oil

Pros:

Food Safe: Like mineral oil, coconut oil is safe for contact.

Pleasant Aroma: Coconut oil imparts a pleasant, tropical scent to the cutting board.

Natural Moisturizer: It helps retain moisture within the wood, preventing drying and cracking.

Cons:

Potential Allergen: Some individuals may be allergic to coconut oil.

Solidifies at Cooler Temperatures: Coconut oil can solidify at cooler temperatures, making it harder to apply.

How to Use: Apply coconut oil like mineral oil, ensuring it’s melted if solidified.

2. Olive Oil

Pros:

Widely Available: Olive oil is commonly found in most kitchens.

Natural and food Safe: It’s a natural oil safe for food contact.

Cons:

Can Turn Rancid: Unlike mineral oil, olive oil can turn rancid over time, imparting an unpleasant taste and smell to food.

May Not Provide Adequate Protection: Olive oil may not provide the same protection and moisture retention level as mineral oil.

How to Use: Olive oil can be applied similarly to mineral oil but should be used cautiously due to its potential drawbacks.

3. Beeswax and Oil Mixture

Pros:

Enhanced Protection: A mixture of beeswax and oil (such as mineral or coconut oil) provides a thicker coating, offering enhanced protection.

Natural Ingredients: Both beeswax and natural oils are food safe.

Cons:

More Complex Application: The mixture must be melted and combined, making the application process more complex.

Potential Cost: This mixture may be more expensive than oil alone depending on the ingredients used.

How to Use: Melt the beeswax and combine it with the chosen oil, then apply it to the cutting board as you would with mineral oil.

Choosing the Right Mineral Oil

Selecting the right mineral oil for your cutting board is crucial to ensure both the longevity of the board and the safety of the food prepared on it. With various options available in the market, it can be challenging to know what to look for. Here’s a comprehensive guide to help you choose the best mineral oil for your cutting boards:

1. Look for Food-Grade Mineral Oil

Why It’s Important: Food-grade mineral oil has been specifically processed and refined to meet safety standards for food contact. It’s odorless, tasteless, and won’t turn rancid, ensuring that it doesn’t affect the flavor of your food.

Tip: Always check the label for a clear indication that the mineral oil is food grade. If it doesn’t explicitly state that it’s suitable for food contact, it’s best to avoid it.

2. Consider the Viscosity

Why It’s Important: The viscosity of the mineral oil affects how easily it can be applied and how well it penetrates the wood. A medium-viscosity oil is typically ideal for cutting boards.

Tip: Look for mineral oil specifically designed for wood cutting boards, as it will likely have the optimal viscosity for easy application and effective protection.

3. Check for Additional Ingredients

Why It’s Important: Some mineral oils may contain added ingredients like vitamin E or beeswax, enhancing the oil’s protective qualities.

Tip: Read the ingredient list to understand what’s included in the mineral oil. If you prefer a pure product without additives, ensure the label confirms this.

4. Evaluate the Packaging

Why It’s Important: The packaging should provide clear instructions on using the mineral oil and any specific precautions.

Tip: Choose a product with user-friendly packaging, such as a bottle with a controlled pour spout, to make the application process more manageable.

5. Consider the Price

Why It’s Important: While mineral oil is generally an affordable option, prices can vary based on brand, quality, and any added ingredients.

Tip: Compare different products within your budget to find the best value. Remember, the cheapest option may not always be the best choice, especially if it compromises on quality or safety.

Maintenance Tips

Maintaining a cutting board goes beyond just oiling. Proper care and attention can significantly extend the life of your cutting board, keeping it functional and aesthetically pleasing. Here are some essential maintenance tips to help you take care of your cutting boards:

1. Regular Cleaning

Why It’s Important: Regular cleaning prevents the buildup of food residues and bacteria, ensuring a hygienic surface for food preparation.

Tips: Use mild soap and warm water to clean the cutting board after each use. Avoid using harsh chemicals or abrasive scrubbers that can damage the wood. Allow the cutting board to air dry completely to prevent moisture from being trapped in the wood.

2. Frequency of Oiling

Why It’s Important: Regular oiling with mineral oil or other suitable alternatives helps retain moisture and prevent cracks.

Tips: Oil the cutting board at least once a month or more frequently if it appears dry. Follow the guidelines provided in the section on applying mineral oil.

3. Avoiding Excessive Moisture

Why It’s Important: Excessive moisture can cause the wood to swell and crack over time.

Tips: Never soak the cutting board in water or put it in the dishwasher. Wipe off excess moisture immediately and allow the board to air dry.

4. Using Both Sides

Why It’s Important: Using both sides of the cutting board ensures even wear, prolonging its life.

Tips: Rotate the cutting board regularly to distribute wear evenly.

5. Monitoring for Damage

Why It’s Important: Over time, cutting boards may develop deep scratches, cracks, or other damages that can harbor bacteria.

Tips: Inspect the cutting board regularly for signs of damage. If the damage is extensive, consider replacing the cutting board to ensure food safety.

6. Storing Properly

Why It’s Important: Proper storage prevents warping and other potential damages.

Tips: Store the cutting board flat in a dry area away from direct sunlight or heat sources.

Product Recommendations

Maintaining your cutting board requires the right products, from mineral oil to the cutting board itself. Here are some top-rated recommendations for both mineral oil products and cutting boards:

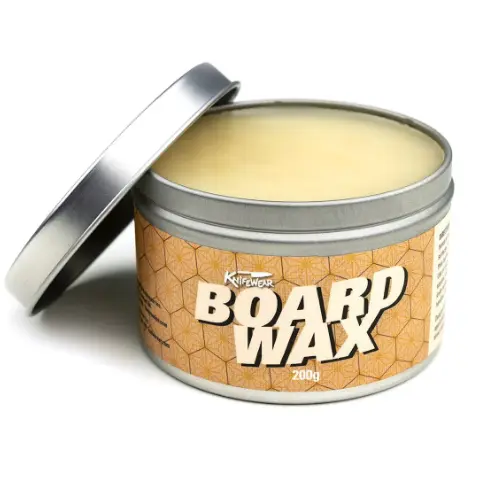

Knifewear Cutting Board Wax – CAD 24.00

Description: A blend of beeswax and mineral oil, this compound keeps cutting boards moisturized and beautiful.

Review: Ideal for those looking for a natural solution with added beeswax for enhanced protection.

Butcher Block Conditioner – USD 11.95

Description: A combination of pure USP-grade mineral oil, beeswax, and carnauba wax.

Review: A versatile conditioner suitable for butcher blocks and cutting boards, offering a blend of quality ingredients.

EndGrain Accessories – USD 36.99

Description: A 3-Part Complete Care System formulated for top condition and longevity.

Review: A comprehensive care system for those seeking a complete solution for cutting board maintenance.

Cutting Board Conditioner – CAD 12.73

Description: Specially designed for Larch Wood Cutting Boards, apply monthly for longevity.

Review: A targeted solution for specific wood types, offering regular care and preservation.

Cutting Board Cleaner – USD 7.95

Description: Effectively cleans and neutralizes odors on well-used wood-cutting surfaces.

Review: A great addition to your maintenance routine, ensuring cleanliness and odor control.

(Note: Prices and availability are subject to change. Always check the latest information on the product’s webpage.)

The Science Behind It

Mineral oil’s use in cutting board maintenance is not just a culinary tradition; it’s grounded in science. Understanding why and how mineral oil works to preserve wood and prevent bacterial growth can provide valuable insights into this common kitchen practice. Here’s a deeper look into the science behind using mineral oil on cutting boards:

1. Mineral Oil and Wood Preservation

Hydrophobic Nature: Mineral oil is hydrophobic, meaning it repels water. When applied to a wood cutting board, it forms a barrier that prevents water from penetrating the wood fibers. This helps in preventing the wood from swelling, warping, or cracking.

Moisture Retention: While repelling external moisture, mineral oil also helps retain the natural moisture within the wood. This balance ensures that the wood doesn’t become too dry and brittle, thus preserving its integrity and appearance.

Compatibility with Wood: Unlike other oils, mineral oil doesn’t oxidize or turn rancid. It remains stable and doesn’t react with the wood, making it an ideal choice for long-term preservation.

2. Antibacterial Properties

Creating a Hostile Environment: By forming a barrier against moisture, mineral oil creates an environment less hospitable to bacteria. Most bacteria thrive in moist conditions, so mineral oil indirectly inhibits bacterial growth by reducing water availability on the cutting board’s surface.

Ease of Cleaning: The smooth, oiled surface of a cutting board treated with mineral oil is easier to clean. This ensures that food residues, which can harbor bacteria, are effectively removed, contributing to overall hygiene.

3. Food Safety Considerations

Non-Toxic and Inert: Mineral oil is non-toxic and inert, meaning it doesn’t react with food or impart any taste or odor. This makes it safe for food contact, unlike other oils or treatments that might affect food quality.

FDA Approval: Food-grade mineral oil meets the Food and Drug Administration (FDA) standards for safety in food handling applications. This adds an extra layer of assurance for those using mineral oil on cutting boards.

Frequently Asked Questions

Using mineral oil on cutting boards often raises questions and sometimes misconceptions. Here’s a comprehensive guide to some of the most frequently asked questions about using mineral oil on cutting boards:

What is the Difference Between Food Grade Mineral Oil and Regular Mineral Oil?

Food-grade mineral oil is specifically refined and processed to meet safety standards for food contact. It’s odorless, tasteless, and approved by the FDA for use in food preparation areas. Regular mineral oil, on the other hand, may contain impurities or additives that make it unsuitable for food contact. Always choose food-grade mineral oil for cutting boards to ensure safety.

Can Mineral Oil Be Used on All Types of Wood Cutting Boards?

Yes, mineral oil can be used on wood cutting boards, including hardwoods like maple and softwoods like pine. It’s a versatile oil compatible with different wood types, providing protection and preservation.

Is Mineral Oil the Only Option for Cutting Board Maintenance?

While mineral oil is a popular choice, there are alternatives like coconut oil, olive oil, and beeswax mixtures. Each alternative has pros and cons, depending on personal preferences and specific needs.

How Often Should I Apply Mineral Oil to My Cutting Board?

The application frequency depends on the cutting board’s usage and condition. Generally, oiling once a month or when the wood appears dry is recommended. Regular inspection and maintenance ensure optimal results.

Can I Use Mineral Oil on Bamboo Cutting Boards?

Yes, mineral oil can be used on bamboo cutting boards. Bamboo is a type of grass, but it behaves similarly to wood in many ways. Applying mineral oil to bamboo cutting boards helps maintain their appearance and functionality.

Is Mineral Oil Harmful to Health?

Food-grade mineral oil is considered safe for food contact and is not harmful to health when used as intended. Ensure the mineral oil you choose is labeled as food grade to guarantee its safety.

Can I Use Mineral Oil on Plastic or Composite Cutting Boards?

Mineral oil is specifically beneficial for wood and bamboo cutting boards. Plastic or composite cutting boards typically do not require oil; mineral oil may not benefit these materials significantly.

Final Thoughts

Using mineral oil for cutting boards is more than just a kitchen practice; it’s a science-backed method that ensures the longevity, functionality, and hygiene of one of the most essential tools in food preparation. From understanding why mineral oil works to knowing how to choose and apply it, this comprehensive guide offers valuable insights for culinary professionals and home cooking enthusiasts.

The maintenance of cutting boards is not merely a task but a commitment to quality, safety, and the joy of cooking. By embracing the knowledge and tips in this article, you can transform a simple piece of wood into a lasting partner in your culinary adventures.