The Ancient Egyptians bentwood after having heated it using boiling water. Then, the Thonet company took the steam-bending method to its highest level by making the famous Thonet chairs that are still known today. This was right before the First World War started.

The Thonet bending method keeps the pieces of evaporated wood from moving along their length by blocking them in templates or molds. The templates are then used to bend the wood. Because the piece of wood is blocked, the fibers are bent and pressed together to get a small radius of curvature.

After the wood has been bent, these templates can be used as molds to dry the bentwood. Curving wood with steam is a complicated process that requires tools for evaporation, bending machines, and drying molds for each piece of wood. The blanks will then need to be profiled and milled.

Even though it was complicated, the Thonet method showed that compressed wood could be bent better than uncompressed wood.

The process of bending wood to make furniture has been around for more than a hundred years. Michael Thonet (1796–1871) made his first pieces of furniture at the end of the 19th century, after a lifetime of research and combining design ideas to improve production. These pieces are still used as models today.

Around the same time as Michael Thonet, Samuel Gragg in Boston got a patent for an elastic chair shaped with steam (1808). Carlo Ratti tried out bending-laminating technology in 1920 in Italy. He did this by joining curved pieces with layers of wood.

Carlo Ratti began experimenting with laminated bending in Italy in 1920. He did this by joining curved pieces with layers of wood.

At the start of the 1930s, Alvar Alto and Marcel Breuer used this method to make chairs and armchairs out of wood with curved shapes.

Inspired by the furniture, they used curves and tubular metal sections in their early designs, making them the first people in the world to use this method.

Laminate can also be used to build architectural spaces. The first design made with this system was made in 1890, and Karl Friedrich Otto Hetzer got the first patent for making straight beams in Switzerland in 1901.

In 1906, Hetzer got a patent in Germany for curved pieces of laminated wood. This was the start of the development of wooden arches worldwide.

For solid wood to be bent, the pieces must first be softened to be bent later. This is done by steaming the wood.

Before this step, a mold with the shape called for by the product’s design must be made. The mold can be made from metal, plastic, wood, and other things.

This process is based on how many parts are made and what resources are available. In countries like Chile, the multi-laminate method makes parts and pieces that are only curved.

The solid wood bending system can be carried out by vaporized, vacuum vaporized, macerated, and chemical treatments.

Wood comprises cellular fibers composed of rigid cellulosic polymers in a lignin and hemicellulose matrix. Lignin is a thermoplastic polymer that softens when heated. It is three-dimensional, amorphous, branched, and thermoplastic. This polymer is in the middle lamella, between S3 and S2.

All amorphous (like lignin) or partially amorphous polymeric materials have a temperature at which they change from one state to another.

Below the glass transition temperature, the substance is in a solid state that is fragile and brittle, like glass. Above the glass transition temperature, the substance becomes liquid or rubbery.

About 338°F is the temperature at which lignin in the matrix turns to glass.

Above this temperature, the lignin can return to a liquid or malleable state, and when the temperature is lowered, it can return to its original shape.

This is the main idea behind how wood can be bent. The temperature at which the matrix turns to glass can be lowered by adding water, softeners, or plasticizers.

Laminating wood can be steamed in the air or under low pressure or heated wet wood in a microwave until its moisture content is between 20% and 25%.

For wood with a moisture content of 20% to 25%, the plasticizing process should take about 38 minutes per inch of thickness.

Wood can be made flexible by treating it with high-pressure steam, but wood treated with high-pressure steam doesn’t bend as well as wood treated at atmospheric or low pressure. Less time is needed to heat something in a microwave.

Several chemicals can be used to make wood more flexible. Chemicals like urea, dimethyl, low molecular weight phenol-formaldehyde resin, dimethyl sulfoxide, and liquid ammonia make wood more flexible.

Urea and dimethyl have yet to get much attention from businesses, and a way to bend wood using liquid ammonia has already been patented.

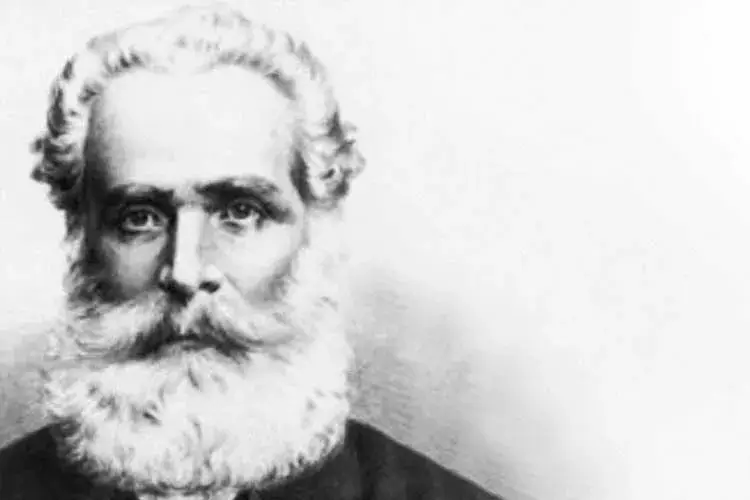

The inventor of bentwood furniture

Michael Thonet also laid the first stone for its industrial production. He was born in 1796 in Boppard am Rhein, where he founded his workshop in 1819.

The son of a master tanner (Franz Anton Thonet) later learned the carpentry trade to establish himself as a self-employed cabinetmaker and created his workshop in Boppard on the Rhine in 1819.

This carpentry workshop is the origin of the current Thonet company. This family business continues to manufacture bentwood furniture and is known worldwide thanks to its high-quality furniture and philosophy characterized by the combination of aesthetics, function, and form.

During the 1830s, Michael Thonet began experimenting with glued and bent wooden slats to make furniture. From that work came his first success, the Boppard chair (1936). In these years, he also acquired the Michelsmühle, a glue factory that gave him more independence.

In 1941 Prince Klemens Wenzel von Metternich declared himself enthusiastic about his designs, which resulted in a great opportunity for the designer. A year later, he could present his designs, especially the chairs, to the imperial family.

After this success and the financial difficulties that the Boppard workshop was going through, he decided to sell it and move the entire family to Vienna to begin working with his children on the decoration of the Liechtenstein Palace.

Also, in the year 41, he obtained the patent for the hot bending of wood and the consequent improvement in the organization on an industrial scale.

In 1849 he reopened a shop with his sons; four years later, he transferred the company to his descendants under the name Gebrüder Thonet.

In 1850 he created Chair No. 1; in 1851, he received the bronze medal at the Great Exhibition in London for his bentwood chairs. A few years later, in 1855, he was again awarded the silver medal at the Universal Exhibition in Paris. He opened a new factory in Korycany (Moravia, Czech Republic) a year later.

In 1859 Thonet created chair no. 14, the chair of the Viennese café that is still known as “the chair of chairs.” It is estimated that it has occurred 50 million times and continues to occur today. It is the first chair that began to be manufactured thanks to its folding technique industrially.

The chair could be disassembled in a few elements and exported to the world in simple packages. In a box of one cubic meter, 36 disassembled chairs could be stored.

Thanks to this chair, the Thonet company became a global company, giving rise to more symbolic designs such as the rocking chair No. 1.

To this day, the family business is in the hands of the direct descendants of Michael Thonet, and the fifth and sixth generations are linked to the company as sales partners and associates.