What is thermally modified wood (Thermowood)

With thermal modification, the wood is heated between 180 to 210 degrees with steam in an oxygen-depleted room without chemical agents.

This heating changes the composition and structure of the wood and extends its lifespan. The wood gets changed properties through heating, such as increased durability, improved dimensional stability (less chance of deformation), and a beautiful warm brown color.

Due to the modification, the wood has also acquired a warm, brown color, whereby the natural wood drawings come to the fore even more beautifully.

Thermal modification of the wood ensures that there is less moisture in the wood. As a result, thermally modified wood has a longer lifespan and is more resistant to wood rot and fungi.

Softwoods such as Spruce and Pine are particularly suitable for this process. The process uses only heat. So very environmentally friendly!

Softwood, in particular, is suitable for thermal modification. Using thermal modification, softwoods can go from durability class 5 to class 2 or even 1. This processing process can also be beneficial for other types of wood.

Thermally modified wood brands

Different versions of high-temperature treatment were developed depending on the country where the upscaling of the basic processes took place.

If you have searched for thermally modified wood before, you have probably come across Thermowood and LunaWord.

These are not abbreviations or collective names for the modification process but trade names.

ThermoWood®

In Finland, several companies have united under the ThermoWood® label for quality control and information provision.

A high-temperature treatment and water steam obtain the Finnish products marketed under the ThermoWood® brand in adapted drying ovens.

Thermowood product includes:

- Thermowood Cladding

- Thermowood Decking

- Thermowood Flooring

- Sauna Material

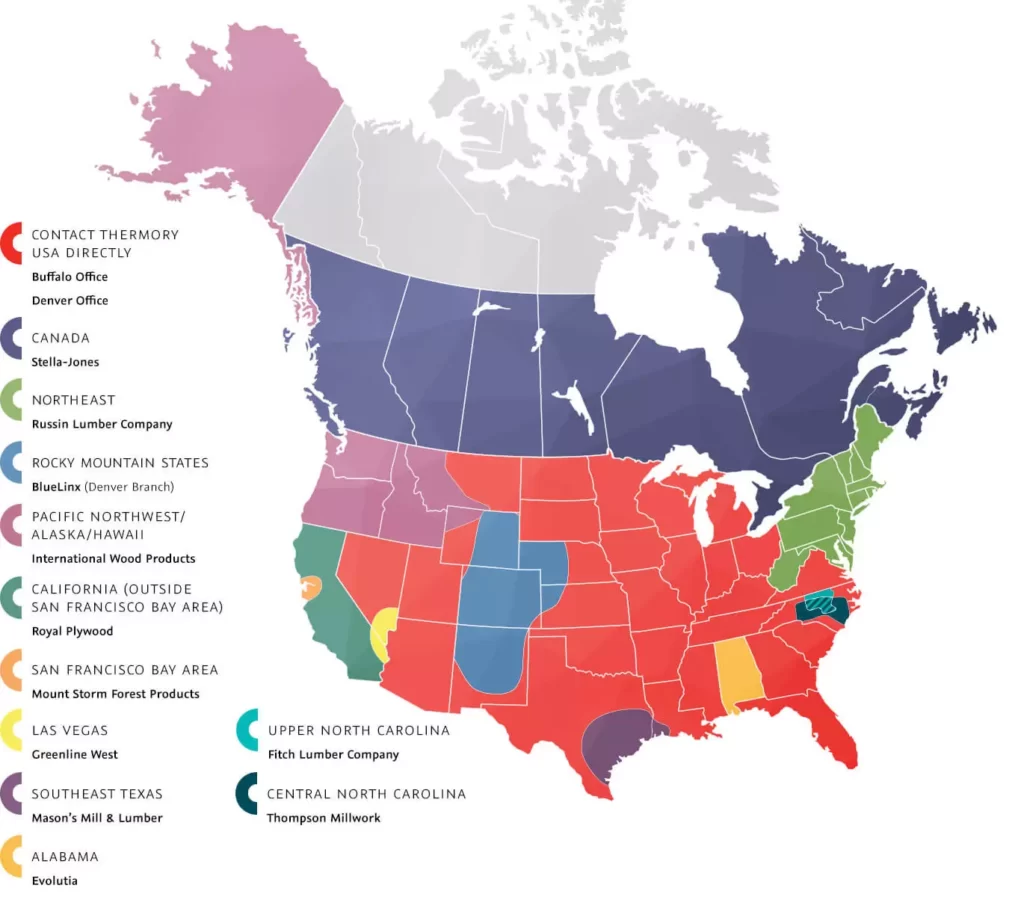

There are five thermo-treatment wood production plants currently in the USA and Canada. The Westwood thermo-modification plant in Macon is the biggest in the North American market.

Plato®

Based on Shell’s findings in the Netherlands, work was done on a phased process, better known under the commercial name Plato®.

Bois rétifié®

In France, initiatives to scale up to have been underway for some time, several of which are based on the findings in ‘L’école des mines de St-Etienne.’ These processes are carried out under a nitrogen atmosphere and often at a slightly higher temperature than in Finland.

Thermally modified wood problems

The best type of wood to choose depends on the application and the desired lifespan. If you have a limited budget, you can choose to build a terrace from impregnated decking boards.

Such a terrace does not last as long as a terrace in thermally modified wood, But costs a lot less. The same applies to a wooden garden shed or carport.

Screwed wooden garden fences are only available in pressure-treated wood or hardwood.

If you have a larger budget and find the lifespan and the environmental aspect important, it is best to choose thermally modified wood.

You are then assured of a long lifespan and that no harmful chemicals can be released from the wood.

When it comes to facade cladding, you have little choice: thermally modified wood or hardwood. Pressure-treated siding is not suitable for facade applications.

Advantages of thermally modified wood

- Light in weight and very dimensionally stable

- 100% environmentally friendly

- Widely applicable for outdoor constructions

- Durability class 1-2

- A longer service life with a higher durability class

- A very environmentally friendly and sustainable process

- No use of chemicals and no harmful substances released

- Better resistant to (wet) weather conditions

- The wood gets a nice warm brown, sometimes golden brown color

Disadvantages of thermally modified wood

- Reduced strength

- Darker in color

- Thermo wood is more brittle; dropping the pieces can damage the edges.

Treating thermally modified wood

Thermally modified woodworks can gray over time. Would you rather not?

Then treating Thermowood is a solution. Using a transparent or opaque stain protects the wood against discoloration.

There are many types of transparent oils, with or without color. There are also different types of transparent and opaque stains on the market.

With these products, you can simultaneously protect your thermally modified wood as it discolors beautifully. By combining Thermowood with stain or oil, you ensure the maximum lifespan of your wood!

Note: pickling is only necessary when it starts to gray.

Which stain is suitable for thermally modified wood?

Roughly there are four options for the types of wood and processing methods

- Leave the wood untreated

- Using a semi-transparent pre-greyer

- Keep the warm wood color as much as possible

- Treat the wood (semi-) opaque

The price difference between pressure-treated wood and thermally modified wood

Pressure-treated wood is about twice as cheap as thermally modified wood; Decking made of pressure-treated lumber, for example, costs an average of $25 to $30 per m².

For thermally modified wood planks, you pay about $50 to $55 per m².

Despite the shorter lifespan, pressure-treated wood can sometimes be more attractive than thermally wood. But first, learn how to dry pressured-treated wood.

Advantages of pressure-treated wood compared to thermally treated wood

+ Cheaper than hardwood and thermally modified wood

+ Better bending and tensile strength

+ Good resistance to wood attack by insects

Disadvantages of pressure-treated wood compared to thermally treated wood

– Shorter lifespan than thermally modified wood (10-15 years compared to 15-25 years)

– Less environmentally friendly (due to treatment with chemicals)

– pressure-treated wood may temporarily show stains (green or salt stains due to the impregnating agent). This discoloration slowly disappears under the influence of sunlight.

The lifespan of thermally modified wood

pressure-treated wood has a shorter lifespan than thermally modified wood but is cheaper and resistant to bending stress. That is why there are screwed garden screens made of impregnated wood and hardwood, but not thermally wood.

The lifespan of pressure-treated wood is approximately ten to fifteen years and depends mainly on the type of wood and the degree of moisture load.

For example, a pine garden fence in direct contact with ground moisture will have a shorter lifespan than a garden fence mounted above the ground on a concrete slab. The wood can then dry out naturally.

Application of thermally modified wood

Thermally modified wood is used in many different ways. Façades and terraces are especially popular.

Yet the wood is also used for fences, roofs, and other wooden constructions!

Thanks to thermal modification, softwoods can become as durable as most hardwoods while being much lighter and more beautiful.

Thermally modified wood is also often much cheaper than hardwood! This is because it is usually made of softwood that grows relatively quickly.

Thermally modified wood almost equals hardwood in life but often costs much less. In addition, it is easier to process due to its lightweight.

Types of wood for Thermowood

We have already indicated that there are different types of wood that are suitable for thermal modification. It is often softwood (pine, poplar, and spruce) used for this purpose and gets the properties of hardwood through the modification process.

Wood types such as ayous, ash, and fraké are used for a more luxurious look with fewer knots and tassels.

Spruce

Spruce is a softwood species that mainly comes from Central and Northern Europe. This affordable option has other advantages in addition to the great price.

Spruce is easier to work with and also virtually odorless. In contrast to pine, this type of wood is characterized by its light color. After the thermal modification, it takes on a nice light brown color.

Pine

Optically, pine and spruce are almost the same, and the properties are also similar in terms of durability.

However, the difference lies in the color and the knots. Pinewood is a bit darker in color and has more large knots. These knots are also less round in pine.

The wood does become a little less flexible as a result of the process. Pine typically contains many tassels. But because Thermowood is darker in color, the knots and tassels are much less noticeable.

Ashwood

Within the types of ash wood, you will find a variation between European and American ash. They are largely similar in properties.

The difference is mainly in the rate at which the tree grows. Where European ash is a so-called fast-growing type of wood, the American variant is the opposite.

The characteristic of American ash is the very clear wood structure.

Ayous wood

Ayous is a tropical softwood, but thermal modification gives the Thermo Ayous the properties of hardwood. It is a white species of deciduous tree native to West Africa.

Like most tropical hardwoods, it has a discreet texture with long-lined patterns. Ayous also has a beautiful warm brown color after the modification process.

This will gradually change to a golden yellow color and then slowly gray (if you choose to leave the wood untreated).

Fraké wood

Would you like a type of wood that gives your project a characteristic look? Then Thermo Fraké is a great option.

This species with a walnut look is durable and creates a unique and luxurious finish. The dark flame structure adds just that little bit extra. Fraké wood reacts quickly to weather influences.

This means that once exposed to sunlight and rain, the wood quickly ages. It needs good ventilation to age nicely.

When you stain the wood, it is recommended to stain all sides. In this way, the chance is considerably smaller than the wood will warp, and you help it age evenly.

Poplar wood

Poplar wood can also be thermally modified. Although the wood species had faded into the background, it is now making a comeback.

Poplar wood originally has a fresh, light color. Thermally modifying the wood gives it a beautiful golden brown color.

Thermo Poplar is very sturdy. Certainly compared to Thermo Ayous, for example, it is a lot less fragile. In terms of appearance, it is very similar to tropical hardwood, despite it being a local type of wood.

American oak

This type of wood also has a rapid natural graying. Although the name suggests otherwise, a lot of wood of this species comes from the Netherlands.

Because the American oak wood grows faster and has fewer natural enemies, it can also be found here more and more.

Even after thermal modification, the wood type is less suitable for load-bearing applications. This is due to the constructive value, approximately 5 to 15% lower than other wood types.

Different surface treatments of Thermowood

This also affects the stain and the materials you have to use for the treatment. Each species also has its own appearance.

Smooth planed wood

The wood is smoothed mechanically by a plane, result that it does not splinter and is suitable for almost all paints and stains.

You can run your hand over the wood without the risk of splinters. Usually, a type of wood gets a sleek look when it is planed smooth. It can be used virtually anywhere in and around the house.

Fine sawn wood

This species gives a more robust appearance than planed wood. Fine sawn wood is often described as wood with a rustic appearance.

The operation consists of two parts; first, the wood is planed smooth and then finely sawn.

Because it comes directly from the sawmill, there is a greater chance of a difference in thickness and roughness. You mainly see this variant with facade cladding, garden houses, and fences.

Because this wood is rougher, it is advisable to use a flat brush with long bristles and to choose a well-covering paint or stain such as Böhme LignoStain.

Brushed wood

If you want to go for a less standard option, choose brushed wood. By brushing the wood with a metal or wire brush, the wood grain comes out very nicely.

Only softwood is suitable for this processing. Think of pine, spruce, and oak. With hardwood, it isn’t easy to loosen the wood around the grain with a brush.

Now that you’ve been able to delve into the processing methods, it’s time to look at the wood species.

Smooth planing or fine sawing is possible with all types of wood. Brushing is, therefore, more ideal on softer woods.

In general, Thermo Firing and Thermo Pine are the most common. The reason is simply the availability and the price. It is the most affordable option.

In addition to these two types of wood, several other options exist, from simple to exclusive.